Descrição

Working principle

1. Different kinds of raw materials are weighed by the metering belt, and enter into the mixer to mix —Batching system (If

your raw material is single, no need this process)

2. We use bucket elevator lift the material up to the silo.—-Bucket elevator and Silo

3. The DH series compactor compress the raw material by double rollers, it mainly depending on the mechanical pressure to compress the dry powder, so the hardness of semi-product is very high.———DH series compactor (including three parts: dosage screw feeder, forced feeder and flaking machine.)

4. Then we get the bar shape products,so we need a crusher to crush the bar shape products into 2-4mm irregular granules.—-Crusher (you can decide the size of granules, we will design the size of crusher mesh.)

5. Finally, we will use rotary screen to sieve the final products, the unqualified products, such as dust, big granular and very

small granular will be recycled for the next time granulation process. You will get the qualified 2-4mm irregular shape granules successfully.——–Rotary Screen

6. Next we use the second time rotary screen, the purpose is we want to get better result of irregular shape granules after

second time screening, the appearance of irregular shape granular will looks more beautiful. ——-Second Time Rotary Screen (if you don’t need this, you can delete this process,Or you can choose coating machine for spray anti-caking agent.)

7. The last step is automatic packaging machine. This machine will help you pack the final granular into bags. —-Packaging Machine(25-50kg/bag or big jumbo)

8.Workshop dusts mainly come from the crusher, screening and discharging port of bucket elevator, in order to effectively

remove the dust, this process uses two stages of dust removal. A cyclone dust collector is used to remove the larger particle dust, and then the bag dust filter is used to remove the residual dust. The dust from the dust collector will return to the granulation process by scraper conveyor.—— Dust collecting process.

Applicable material and finished product.

Technical Parameters of DH series compactor

| Modelo | DH360 | DH450 | DH650 | DH850 | DH1050 | |

| Roller diameter (milímetros) |

φ360 | φ450 | φ650 | φ850 | φ1050 | |

| Valid usable width (milímetros) | 220-300 | 270 | 320 | 420 | 450 | |

| Roller speed (rpm) |

10-25 | 10-25 | 10-25 | 9-16 | 8.5-14.5 | |

| Max rolled sheet thickness(milímetros) | 8 | 12 | 16 | 25 | 36 | |

| Finished product output (ton per hour) |

0.7-1 | 1.5-2 | 3-3.5 | 5–6 | 10-13 | |

| Granule size(milímetros) Can be customized | 2-5 | 2-5 | 2-5 | 2-5 | 2-5 | |

| Compactor power (KW) | 30-37 | 55-75 | 90-110 | 220-250 | 400 | |

| Total line power (KW) | 55 | 90 | 175 | 400 | 850 | |

| External dimension (milímetros) | 2350×2000×2600 | 2600×2200×2900 | 3600×2800×3200 | 5,000×3,800×4,100 | 7,000×5,000×6,000 | |

| Total weight (t) | 7 | 10 | 21 | 46 | 85-90 | |

Peripheral equipment

In addition to the compactor, we can also provide the whole supporting equipment of granulating process to help you finish the granulating much better. Such as the mixer, crusher,screening machine,screw conveyor, scraper convayor, bucket elevator, package machine, drying/cooling machine, máquina de revestimento, polishing machine and so on.

If you choose Normal button control, It is composed of the electrical components such as electric control box, frequency conversion controller, ammeter, voltage meter, light, button switches, voltage switch and so on. All the electrical equipment is controlled and operated concentratedly.

If you choose PLC automatic control,The control system is used for granulating equipment system, including central control system, power cabinet, field actuator (such as motor, solenoid valve, etc.), which is controlled by PLC, and communicated by international standard communication protocol or TCP / IP mode. The central control system inputs instructions by upper computer, and PLC sends output instructions to field equipment to complete automatic control Control and reserve remote DCS interface.

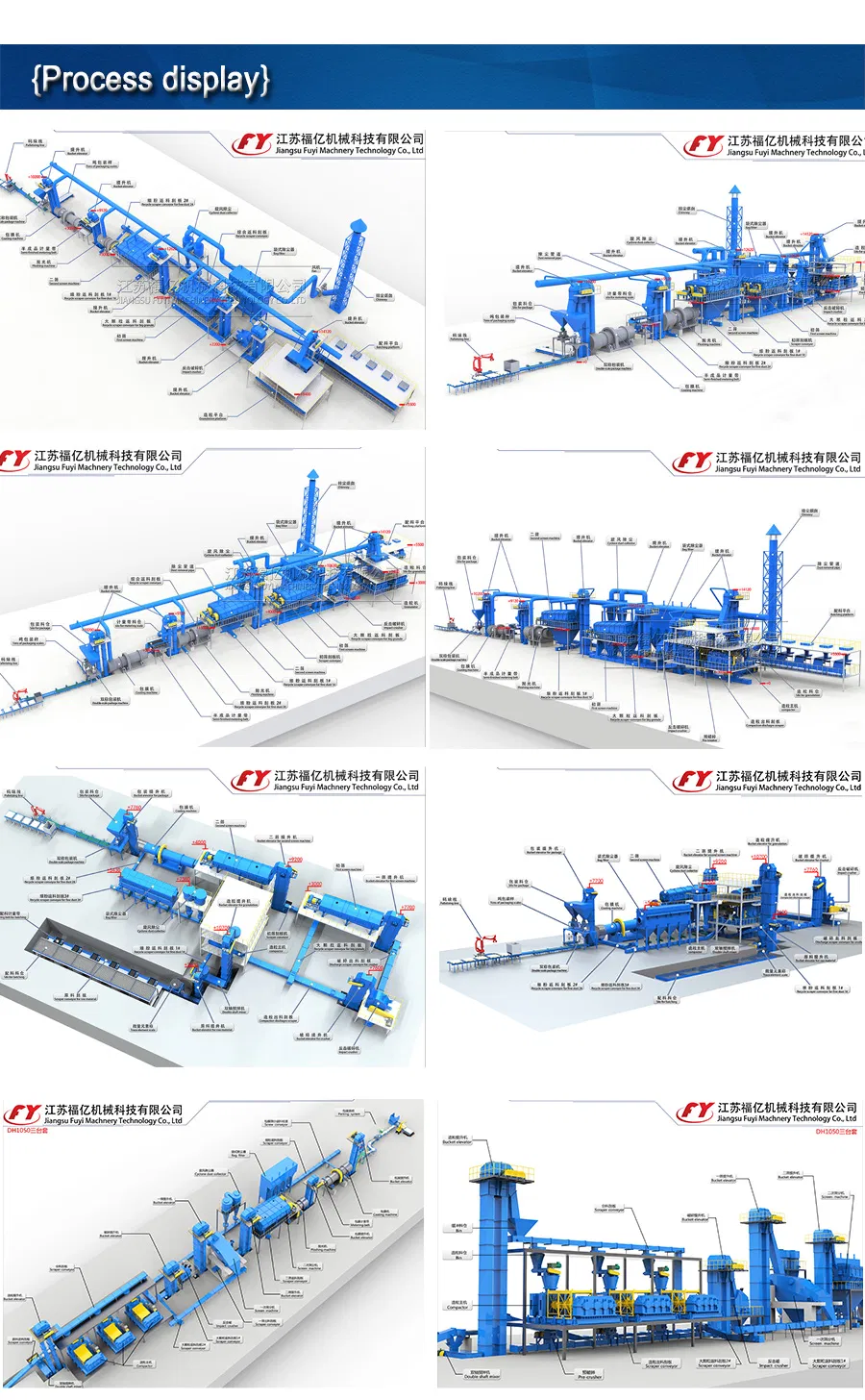

Layout

We can design different diagram for different clients, we need to design the layout according our clients provide us some basic information about the size of their factory, and how do they want to place the equipments. Our target is making the process more simple , more easy, more economic and more effective.

Customer site